Products

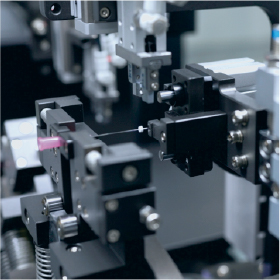

Auto-Production Machine System

- Requirements Analysis and Planning

-

At the initial stage of the project, conducting a precise analysis of the required types of medical devices, production volume, quality standards, etc.

- Design and Development

-

The design of automated equipment is based on requirements analysis, determining equipment layout, necessary machinery and robotic systems, control systems, etc.

- System Integration

-

At the initial stage of the project, conducting a precise analysis of the required types of medical devices, production volume, quality standards, etc.

- Requirements Analysis and Planning

-

Integrating individual equipment and systems into a single operational automation line, involving not only mechanical connections but also software and control system integration.

- Testing and Validation

-

Testing equipment to ensure it operates accurately as per the design and verifying it meets required quality standards and safety requirements.

- Operation and Maintenance

-

Once the automation equipment is operational, conducting continuous monitoring for stable system operation and performing regular maintenance.

- Continuous Improvement and Upgrades

-

Continuously improving the system in line with market changes and production demands, and upgrading as necessary.

-

Product introduction

제품 보러가기

Production Equipment

-

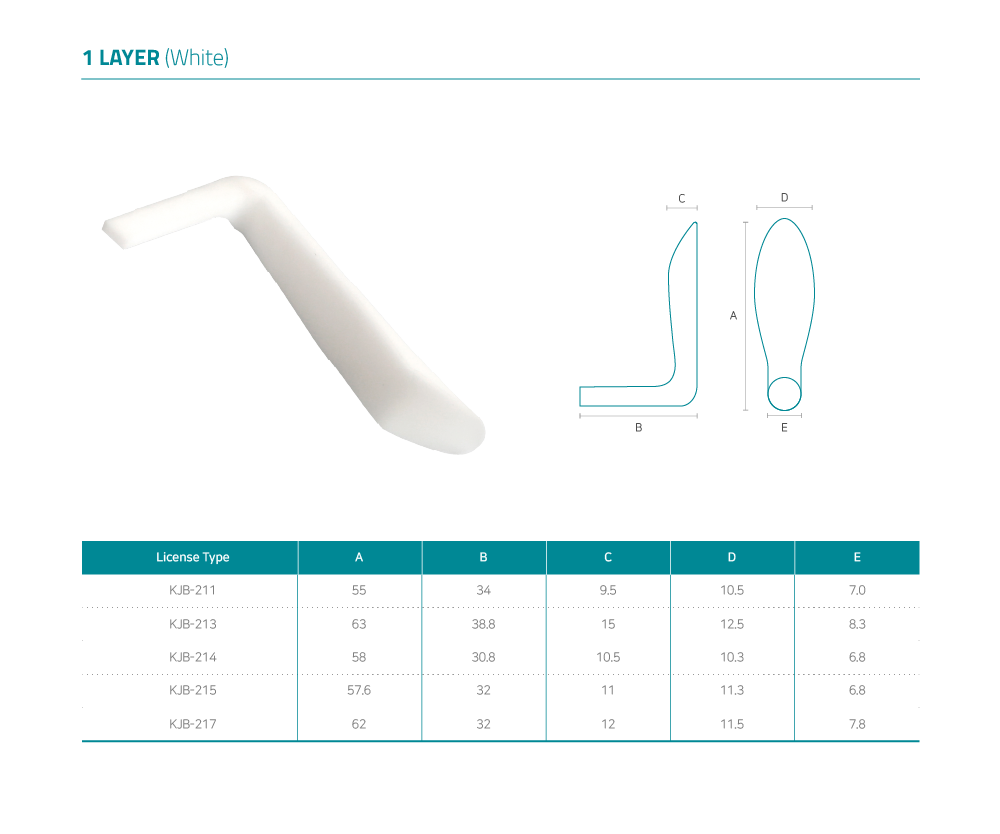

Medical Device Automated

Production Equipment·MONO Product

·COG Product

·MOLD Product

·SURGICAL SUTURE

·Assembly Machine -

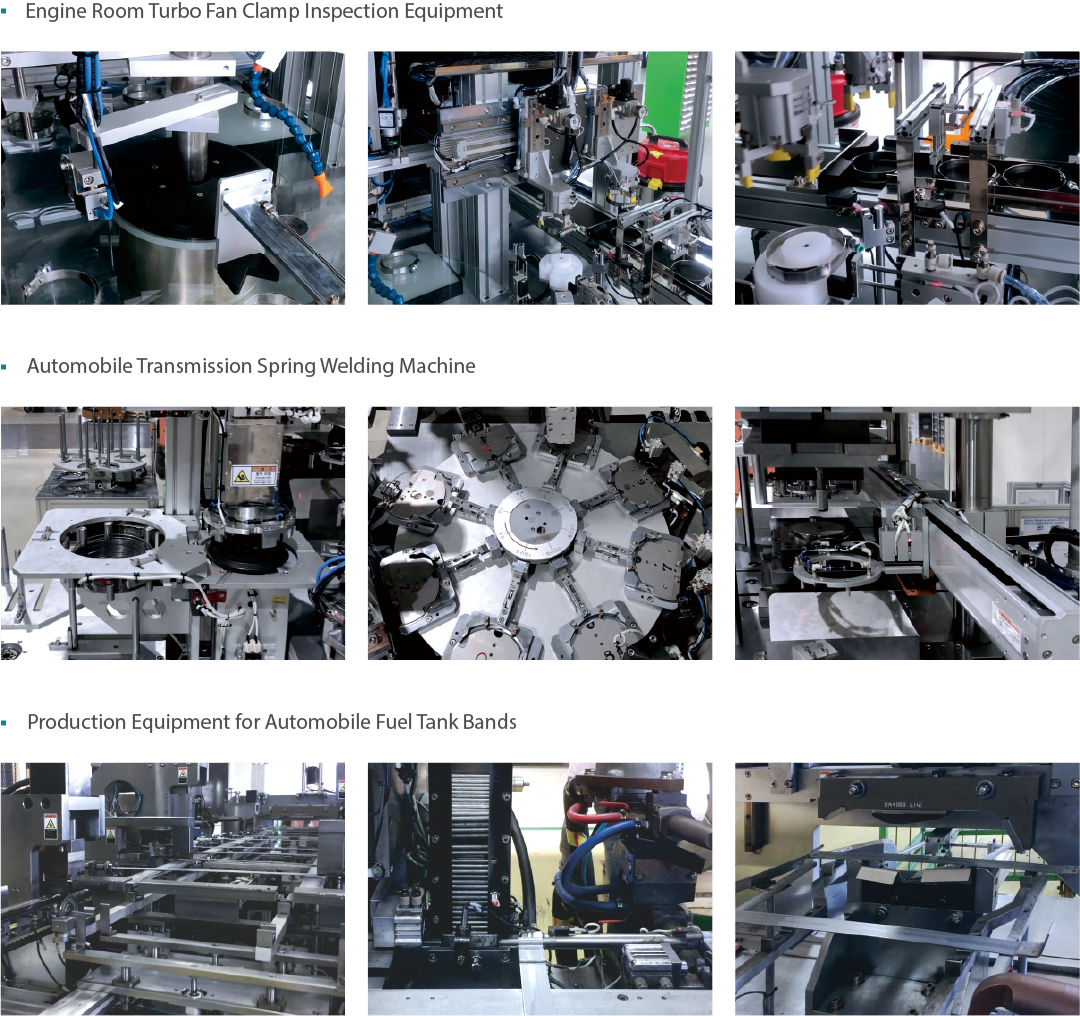

Automated Automotive Parts

Production Equipment·Transmission Spring Production Equipment

·Automated Equipment for Fuel Tank Band -

Automated Electronic Component

Production Equipment·Battery

·Electronic Gun Welder

·Sash Laser Welding

Automobile Parts Automation Facility